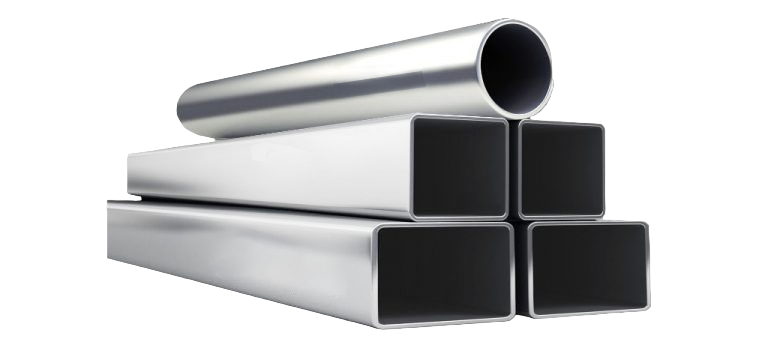

HMT At Duty - Structural Steel Tubes

HMT At Duty offerings are crafted from premium hot-dip galvanized steel coils to meet the demand for galvanized steel tubes in coastal areas. These pre-galvanized tubes boast a substantial coating of Zinc both on the interior and exterior surfaces. The At Duty range serves as an essential solution for roofing structures, affording enduring defense against rain and sunlight, ensuring longevity for generations to come. These options encompass Square, Rectangular, and Circular pipe and tube configurations.

Specifications

Pre-Galvanized Circular, Square, and Rectangular Tubes with a rich coating of Zinc that helps protect against interior rusting of tubes with 120GSM galvanized coating enhance the life of structural steel tubes.

Thickness: 0.6mm to 2.5mm (Higher thickness as per requirement)

Length: 4.0mm to 12.0mm

- At Duty is manufactured using hot-dip galvanized coil, a feature that significantly extends the lifespan of these tubes, ensuring enhanced durability and strength. The internal zinc coating acts as a protective barrier, preventing rusting from within. Engineered for multi-generational durability, these tubes exhibit exceptional resistance to corrosion from elements like wind, water, and road salts, establishing them as entirely rust-proof.

- Reasons to Opt for HMT At Duty: Choosing HMT At Duty offers unparalleled advantages, as these tubes boast an extended lifespan compared to other products. The robust coating delivers exceptional resilience against mechanical damage during transportation, installation, and maintenance phases.

- HMT At Duty exhibits remarkable durability.

- Environmentally friendly with structural steel tubes.

- At Duty comprises rectangular tubes, square tubes, and structural steel tubes that exhibit resistance against atmospheric corrosion.

- The thickness of the coating applied is determined by the specific atmospheric and corrosive conditions of each location.

- APL Apollo’s in-house galvanizing facility meticulously controls the overall appearance and finish.

- Perfectly suited for roofing structures encompassing square tubes, rectangular tubes, and more.

- The standout advantage of HMT At Duty lies in its exceptional corrosion resistance. The zinc coating acts as a protective barrier, safeguarding the steel by sacrificing itself.

- HMT At Duty’s structural steel tubes are inherently self-maintaining and feature a thicker build. Their extended lifespan translates to reduced maintenance costs.

- HMT At Duty is not only optimal for structural applications but also offers a contemporary touch. These hollow steel sections seamlessly integrate metals into indoor and outdoor spaces, enhancing aesthetics.

- These structural steel tubes can be incorporated into residential and commercial environments as exposed structural elements, railings, beams, columns, furniture, and more. The zinc-coated surface enhances both attractiveness and durability.

- Thanks to its exceptional metallurgical bond, HMT At Duty galvanized steel boasts impressive robustness, ensuring prolonged and reliable performance.

- The square tubes within the range exhibit remarkable tensile strength, rendering them highly resilient to extreme temperatures and pressures.

- The higher hardness value of zinc compared to steel provides galvanized hollow steel structures and structural steel tubes with enhanced impact resistance and anti-wear properties, surpassing those of standard steel tubes.

- Due to their inherent durability and resilience, minimal maintenance or repair is necessary.

- The common issue of rusting, particularly in iron and steel components, is mitigated by HMT At Duty through its zinc coating that effectively combats oxidation. The zinc layer acts as a protective barrier against rust formation.

- Both square and rectangular tubes from HMT At Duty boast impressive abrasion resistance, making them well-equipped to withstand challenging weather conditions like wind and rain.

- The structural steel tubes featured in HMT At Duty are skillfully welded with a hot-dip galvanized exterior. This process enhances corrosion resistance and extends the overall service life, ensuring versatile applications for galvanized square tubes.

- Multi-Family Residences: HMT At Duty’s structural steel tubes and hollow steel structures are meticulously engineered to exhibit exceptional resistance against corrosion and cracking. These qualities are especially advantageous in carbonated concrete, showcasing heightened endurance against chloride migration compared to uncoated steel. As a result, these modern living spaces can confidently embrace longevity without compromising on aesthetic appeal and structural integrity.

- Terraced Housing: Set apart by their rust-proof characteristics, HMT At Duty’s structural steel tubes and ERW tubes offer superior resistance against various chemical processes that contribute to corrosion. This inherent resilience not only translates to reduced maintenance requirements but also provides a versatile canvas for both simplistic and intricate design patterns.

- Roofing Solutions: Particularly suitable for roofing structures in high humidity or exposed environments, these ERW steel tubes guarantee enduring performance. Their ability to withstand adverse weather conditions and thwart corrosion resulting from moisture exposure makes them an optimal choice. Additionally, the use of galvanized steel roofing sheets contributes to a lightweight load on the structure, thereby lowering project costs.

- Coastal Applications: With heightened resistance against saltwater-induced corrosion and environmental factors, these hollow steel sections are frequently harnessed in coastal areas. The enduring nature of this steel makes it a preferred option for structures like piers, bridges, and seawalls, offering a reliable defense against saltwater’s corrosive impact while withstanding harsh winds and waves.

- Versatile Fabrication: Recognized for its strength, durability, and ease of customization, hot-dipped galvanized steel from HMT At Duty is a favored choice for fabrication endeavors. Its adaptability in cutting, welding, and shaping lends itself to diverse project requirements. This versatility finds applications in industrial sheds, storage tanks, transportation containers, and beyond.

HMT Steel emerges as the optimal selection for an array of steel structures, PEB structures, structural steel buildings, and construction projects.

PRODUCT APPLICATIONS

STRUCTURAL IN OUR WORLD

Contact us

Forge a Stronger Future with Our Precision Steel Manufacturing – Explore Our Expertise Today