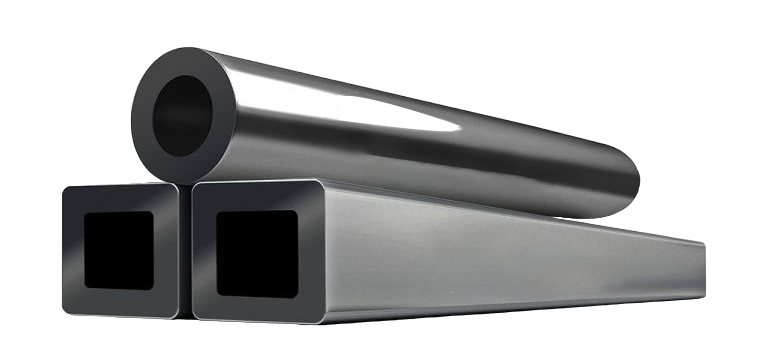

HMT MechMight - Structural Steel Tubes

HMT MechMight tubes embody a slender profile coupled with substantial thickness, finding their application in robust scenarios such as foundational frames for substantial machinery and industrial apparatus, segments for tower crane masts, gantry cranes, trailer hitches, and agricultural equipment. These mechanical tubes excel in their suitability for high-load applications requiring exceptional weight-bearing prowess.

Specifications

Circular Tube

Size: 38.1, 48, 60.3, 71.5, 76.2 and 88.9 mm

Thickness: 3mm to 10mm

Square Tube

Size: 30X30, 40X40, 50X50, 60X60 and 72X72 mm

Thickness: 2mm to 8mm

Rectangular Tube

Size:50X30, 60X40, 70X30, 70X50 and 100X50 mm

Thickness: 2mm to 8mm

Applications

Support Frames for Heavy Industrial Equipment

Heavy Duty Chain Conveyor

Mobile Gantry Crane

Cultivator And Rotavator

Tower Crane Mast Section

Trailer Hitch Tube

Spreader beam

Hydraulic cylinder

Propeller shaft & Axle

Heavy Duty Trailer Frame

Monorail Crane

Harvesters

Sturdy, enduring, and resilient, HMT MechMight tubes present an exceptional range of tubes characterized by amplified dimensions and heightened thickness, showcasing remarkable strength, consistency, and economical attributes. These tubes are distinguished by their formidable mechanical capabilities, a testament to their robust construction.

- Robust Foundations for Industrial Machinery: HMT MechMight lends unwavering stability to hefty industrial equipment, harnessing its exceptional load-bearing prowess.

- Sturdy Chain Conveyance: The implementation of HMT MechMight in the assembly of the support structure for conveyor belts augments the structural integrity and sturdiness of the system.

- Mobile Gantry Crane: The augmented thickness of HMT MechMight equips mobile gantry cranes with heightened load-bearing capacity, bolstering their operational efficacy.

- Tilling and Plowing: HMT MechMight Tubes display a remarkable ability to withstand the substantial strains experienced during tilling and plowing activities in rugged terrain, necessitating minimal maintenance efforts.

- Tower Crane Uprights: Tower crane mast sections benefit from the utilization of low-diameter, high-thickness tubes like HMT MechMight, characterized by uniform strength distribution.

- Trailer Coupling Component: The trailer hitch tube serves as a vital structural interface between tow vehicles and trailers, and HMT MechMight tubes are well-suited for this purpose, especially on larger vehicles.

- Harvesting Efficiency: Employing low-diameter, high-thickness tubes in pivotal structural components of harvesters imparts enhanced strength and operational efficiency.

- Load Spreading Apparatus: Spreader beams, constructed from HMT MechMight, ensure secure lifting and safe handling during various operations.

- Hydraulic Power Transmission: Scarfed mechanical tubes, boasting smooth outer and inner surfaces, find apt application in hydraulic cylinder assemblies.

- Power Transmission Elements: Mechanical tubes are integral to the composition of propeller shafts and axles, facilitating the efficient transfer of mechanical power.

- Robust Trailer Framework: Low-diameter, high-thickness tubes are ideally suited for fabricating robust vehicle frames that excel in carrying substantial loads.

- Monorail Crane Operations: HMT MechMight materials contribute to the seamless mobility and extended service life of monorail crane bridges.

- Rigorous Quality Assurance Throughout: HMT MechMight adheres to stringent protocols at every stage of its manufacturing, guaranteeing the delivery of premium-grade products and solutions.

- Forged by Robust Tube Mills: These structural steel tubes are meticulously fashioned with superior materials and advanced technological tools, reinforcing their heavy-duty attributes.

- Crafted through High-Frequency Induction Welding: The application of high-frequency welding in the fabrication of HMT MechMight’s hollow steel constructs translates to swift welding cycles, economical tooling, a clean manufacturing process, and elimination of subsequent drying or hardening procedures.

- Unyielding Dimensional Precision: An intricate analysis of dimensional tolerances empowers HMT MechMight’s mechanical steel tubes to ascertain optimal component tolerances, thereby ensuring the efficiency, reliability, and full functionality of parts.

- Consistent Strength and Endurance: The intrinsic robustness and tenacity of these structural steel tubes equip them to withstand elevated heat and velocity pressures with unwavering uniformity.

- Empowering Designers and Engineers: Mechanical structural steel tubes and hollow sections furnish remarkable design flexibility across an array of construction projects, encompassing avant-garde architectural endeavors and the establishment of resilient public infrastructure. Their attributes include resolute strength, resistance to corrosion and fire, and an extended lifecycle.

- Extensive Size Variability: HMT MechMight offers an expansive assortment of sizes within its mechanical structural steel tubes, spanning a wide range of diameters and thicknesses.

- Pleasing Aesthetic Finish: Surface finishing emerges as a pivotal facet, ensuring the visual appeal and prolonged durability of metal parts.

- Absence of External Heat Projections or Weld Beads: HMT MechMight’s structural steel tubes dispense with external heat moldings, averting suboptimal designs and potential weld lines across distinct sections of the tubes.

- Streamlined Fabrication: The fabrication process of HMT MechMight encompasses cutting, welding, stamping, and tooling of stainless components, culminating in tube straightness, time and effort savings, prevention of tube twisting, and mitigation of material wastage.

Agricultural Machinery: HMT MechMight tubes consistently rank as the preferred option for both farmers and agricultural technology enterprises in the fabrication of agricultural vehicles. Beyond the inherent durability and robustness of these structural steel tubes, we engineer materials that are sustainable and weather-resistant, essential attributes for ensuring the prolonged longevity of these vehicles, minimizing the need for recurrent maintenance and upkeep.

HMT MechMight stands as the quintessential steel tube choice, characterized by its ERW steel tube composition that translates to enhanced efficiency, reduced costs, and heightened precision. Additionally, it boasts corrosion resistance, strength, an aesthetically pleasing appearance, and an array of further advantages.

HMT Steel emerges as the definitive selection across diverse categories encompassing steel structures, pre-engineered buildings (PEB), structural steel edifices, and construction requisites.

PRODUCT APPLICATIONS

STRUCTURAL IN OUR WORLD

Contact us

Forge a Stronger Future with Our Precision Steel Manufacturing – Explore Our Expertise Today