HMTech Steel Solutions

HMT Steel introduces cutting-edge HMTech Steel Solutions, a groundbreaking advancement in the realm of tubular construction. This innovative approach redefines the landscape of Pre Engineered Buildings (PEB) materials by combining superior quality, cost-effectiveness, streamlined project timelines, and unwavering environmental stewardship. Within the construction sector, the integration of tubular structural steel construction solutions offers an expedited path to enhanced efficiency and superior outcomes.

Specifications

Sizes: 12x12mm to 1000x1000mm

Applications

Building frames

Mechanical and industrial applications

Staircases and railings

Support structures for mechanical equipment

The HMTech Steel Solutions provided by HMT Steel are poised to initiate a transformative era within the tubular construction sector, yielding extensive advantages for all involved parties while fostering a favorable ecological footprint.

Traditional RCC structures typically demand around 155 days for construction, necessitating a substantial labor force that can pose challenges due to scarcity and inadequacy. These structures often incur elevated administrative expenses and encounter budget overruns stemming from project delays. The water demands during construction are also considerably high. Additionally, the rainy seasons can significantly hinder the construction and curing processes of RCC structures. Notably, air and water pollution are frequently associated with RCC construction.

Robust Strength: The tubular configuration exhibits remarkable strength, resisting breakage with exceptional resilience. It demonstrates the ability to withstand both internal and external stressors, encompassing factors like irregular architectural design, misalignment, inadequate coverage, and fluctuating temperature extremes.

Aesthetic Allure: Tubular shapes offer a visually appealing facet as they are amenable to design alterations, such as bending or curving, which contributes to their aesthetic charm.

Sustainability and Eco-friendliness: Tubular steel solutions align with ecological sustainability by minimizing air pollution and conserving water resources. Steel’s recyclability, heightened potency, seismic resistance, and potential for up to 6% additional clear height underscore its eco-conscious attributes.

Enduring Resilience: This material’s durability is two-fold, encapsulating both robustness and adaptability. This versatility renders it suitable for a broad spectrum of construction applications, ensuring the right choice of building material and seamless project execution.

Resilience Against Stress: Possessing impressive tensile strength, this element exhibits pliability and ductility, bestowing it with resistance against fractures. This capacity equips it to effectively counteract external and internal stresses, encompassing architectural irregularities, misalignments, insufficient coverage, and fluctuations in temperature.

Cost-Efficiency: Another pivotal merit of the tubular structure is its cost-effectiveness. The controlled manufacturing environment of modular components curtails waste and errors, culminating in a cost-efficient end product of superior quality.

Tubular construction solutions offer unparalleled versatility, finding optimal application across a spectrum of domains including medical facilities, residential complexes, educational institutions, courts, towering skyscrapers, hospitality establishments, commercial centers, office spaces, storage facilities, warehousing units, frigid storage units, food parks, industrial plants, aviation hangars, data centers, and beyond.

Skyscrapers and High-Rise Structures: Tubular steel’s paramount role is evident in the construction of high-rise edifices. It serves as the stalwart backbone of scaffolding systems, fortified with exceptional mechanical stability and remarkable impact resistance. Additionally, tubular steel elements are progressively employed for reinforcing I-beams and structural linkages within steel framing systems, facilitating the creation of towering structures.

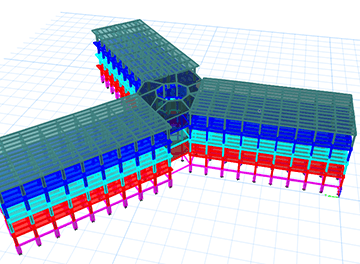

Building Frameworks: Embracing an exceptional strength-to-weight ratio, tubular steel assumes a pivotal role in erecting building frameworks. Its prowess is harnessed in establishing support frameworks for monumental structures such as bridges and stadiums, enhancing the stability and structural integrity of these edifices.

Industrial and Mechanical Applications: Renowned for its durability and strength, tubular steel is a cornerstone in machinery and equipment fabrication. It serves as the building block for conveyor systems, scaffolding, and various other industrial apparatus, capitalizing on its robustness and longevity.

Tubular Structural Steel in Medical and Educational Structures: The versatility of tubular structural steel extends to medical and educational infrastructure. It often forms the cornerstone of hospital and school constructions, providing the essential structural underpinning and stability. Noteworthy applications include:

Staircases and Railings: Tubular steel is a prime choice for crafting staircases and railings within hospitals and schools, capitalizing on its resilience and durability. Withstanding heavy foot traffic and resisting damage, it ensures enduring reliability.

Support for Mechanical Equipment: Tubular steel adeptly supports mechanical equipment like HVAC systems and ductwork within hospital and school premises, underscoring its role in functional infrastructure.

HMTech Steel Solutions is the epitome of excellence, presenting unparalleled choices in structural innovation and construction reliability.

PRODUCT APPLICATIONS

STRUCTURAL IN OUR WORLD

Contact us

Forge a Stronger Future with Our Precision Steel Manufacturing – Explore Our Expertise Today